- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

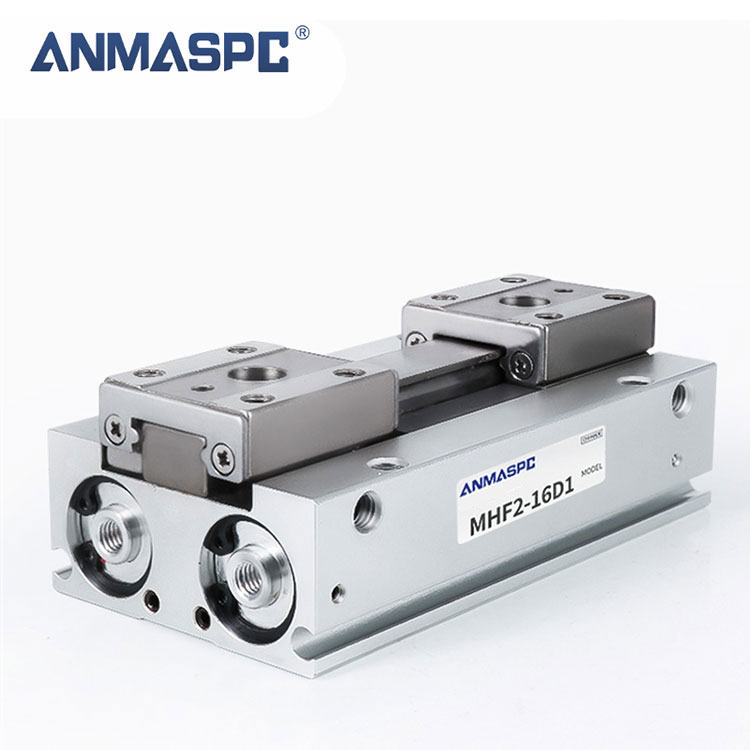

SC series cylinder Pneumatic cylinder Standards-based cylinder

Send Inquiry

SC standard cylinder is a common standard cylinder with the following main features and details:

Structural features:

End cover: adopts new pressure casting processing technology.

Cylinder barrel: uses high-quality aluminum alloy to draw the pipeline, and the internal surface is hard anodized.

Piston rod: the surface is pre-rolled hardened, electroplated with hard chrome and finely ground, with good rust and wear resistance.

Seal: novel structure, excellent quality, can work normally without lubricating oil, low initial starting pressure, and extended service life.

Product features:

Lubrication-free: adopts oil-containing bearings, and the piston rod does not need to be lubricated.

Buffering: In addition to fixed buffering, it also has adjustable buffering, so that the cylinder is smooth and impact-free when reversing.

High temperature resistance: high temperature resistant sealing materials can be used, suitable for high temperature environments of 150 degrees Celsius.

Various installation methods: provide a variety of installation accessories for customers to choose from.

Magnetic attachment: A permanent magnet is installed on the cylinder piston, which can trigger the magnetic switch to sense the movement position of the cylinder.

Precautions for installation and use:

Load change: When the load changes during work, a cylinder with sufficient output force should be selected.

Pipeline cleaning: Before the cylinder is connected to the pipeline, the debris in the pipeline must be cleared to prevent debris from entering the cylinder.

Media filtration: The medium used should be filtered through the filter core.

Low temperature protection: Antifreeze measures should be taken in low temperature environments to prevent moisture from freezing.

No-load test run: Before use, a no-load test run should be carried out, and the buffer should be gradually enlarged to avoid excessive impact.

Side load: Try to avoid side load to maintain the normal operation and service life of the cylinder.

Long-term storage: When it is removed and not used for a long time, attention should be paid to surface rust prevention, and dust-proof plugging caps should be added to the inlet and outlet ports.