- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

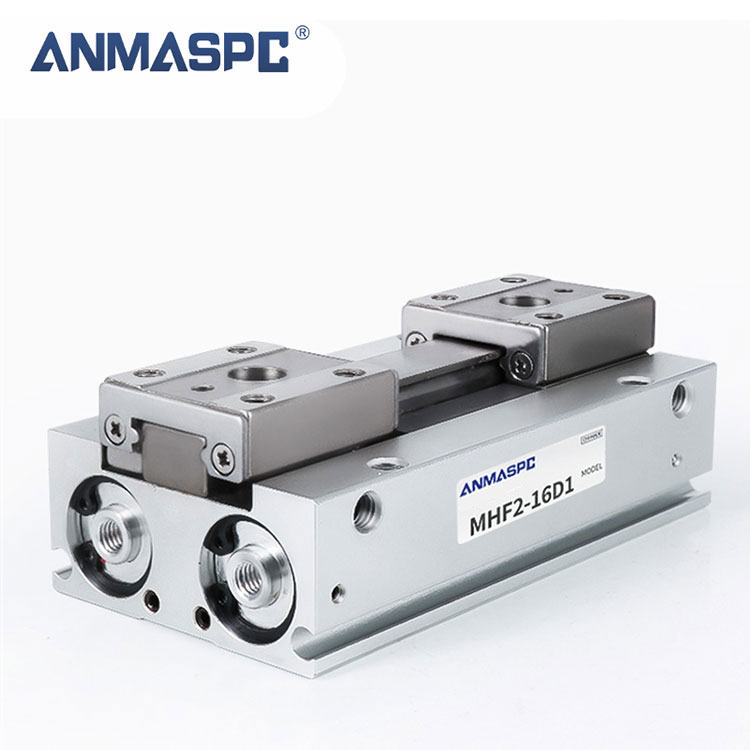

Pneumatic MI series stainless steel cylinder Mini cylinder

Send Inquiry

Features

High efficiency: Mini cylinders can complete work tasks quickly and accurately.

Lightweight: Pneumatic actuators are usually lighter and easier to install and maintain.

Cheap price: Compared with other types of cylinders, mini cylinders have a lower cost.

Compact structure: The overall structure is small and suitable for use in limited spaces.

Application scenarios

Mini cylinders are suitable for the following scenarios:

Small automation equipment: Mini cylinders can provide precise linear motion control when space is limited.

Precision instruments: Mini cylinders can provide stable and reliable performance in applications that require high-precision control.

High-frequency use scenarios: Due to its high efficiency and lightweight design, mini cylinders perform well in high-frequency use scenarios.